Hydrogen Basics: Fuel of the Future Explained

Plug produces and utilizes green hydrogen, an energy carrier many scientists say could serve as a key part of the climate solution in helping to lower greenhouse gas emissions. But what, exactly, is hydrogen?

Congressional climate legislation passed in recent years could serve as a catalyst for the growth of the U.S. renewable energy market, including hydrogen, the core component utilized in Plug’s global energy products. The 2021 Infrastructure Investment and Jobs Act ushered in $7 billion in federal dollars for regional hydrogen hubs throughout the U.S. Furthermore, the 2022 Inflation Reduction Act also will expand the hydrogen market within the U.S. by giving federal tax credits toward the production of green, climate friendly hydrogen.

While many technologies will play a critical role in helping the world to achieve the global consensus “net zero” greenhouse gas emissions by 2050, hydrogen is poised to play a pivotal role in realizing this target. It can be produced in a climate-friendly manner, can be safely and stably stored for long durations, and is versatile in that it can be utilized in a variety of decarbonization methods and industries.

But that begs several questions. What exactly is hydrogen? How is hydrogen produced? What are the different types of hydrogen? What applications is Plug targeting for green hydrogen deployment? And how safe is it?

Answers to these frequently asked questions will not only offer an overview of the basics, but also depict what Plug has to offer as a long-time industry leader that has pioneered green hydrogen’s growth.

What is Hydrogen?

Hydrogen, one of the 118 known elements, is prolific throughout Earth and the rest of the Universe. Hydrogen atoms can be found within other compounds and are even more abundant throughout the atmosphere at-large. Beyond Earth, hydrogen molecules are “also the most abundant element in the universe,” according to the U.S. Energy Information Administration, composing ~75% of the mass of the Universe.

Known by scientists as its chemical element symbol H in its atomic form, bonded hydrogen molecules exist in an incredibly large number of compounds and chemical, ranging from water and ammonia to plants, animals, and even people. It is literally all around (and in) us. Without hydrogen, life as we know it would not exist.

Hydrogen also happens to possess an excellent amount of stored energy. “The energy in 2.2 pounds of hydrogen gas is about the same as the energy in 1 gallon of gasoline,” the U.S. Department of Energy’s Alternative Fuels Data Center details in laying out the basics of hydrogen’s potential as a fuel. This energy can be realized by running the hydrogen through a fuel cell or by directly burning it, both mature technologies.

Here is the challenge. Although hydrogen is incredibly prevalent and around us every day, it is not naturally occurring on Earth. It is generally only present in a compound form with other elements forming gases, liquids, and solids (i.e., water – H2O). Therefore, in order to utilize the hydrogen it must first be extracted. This means that hydrogen can effectively be used as an energy storage medium. Energy is “put in” by extracting the hydrogen which can then be stored (analogous to a battery). When needed, the hydrogen can then be consumed in a fuel cell or combustion application to “release” the energy stored.

How is Hydrogen Produced?

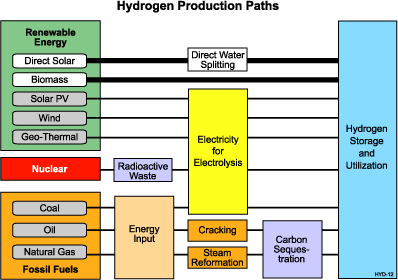

As stated, hydrogen is a critical ingredient to a range of compounds and chemicals, which are produced globally (i.e., ammonia – NH3). What this means is that a hydrogen economy already exists, producing large volumes every year. However, the majority of this supply is made via methods with significant emissions as a byproduct. It is important then to understand the various methods through which hydrogen can be produced and how climate friendly they each are.

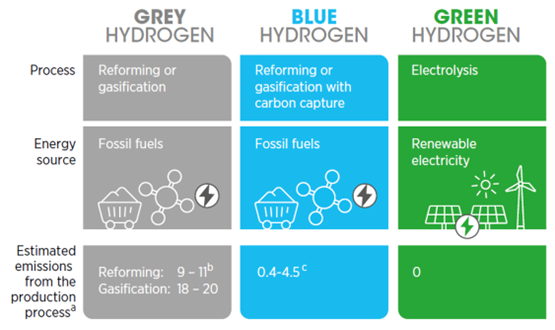

The two most common modes of hydrogen production are steam-methane reforming and electrolysis. In brief, steam-methane reforming involves separating hydrogen molecules from natural gas or splitting the carbon atom from the hydrogen molecules. Water electrolysis uses water as its electricity current to produce hydrogen and therefore can be non-fossil fuel based. At the moment, the majority of hydrogen produced is via steam methane reforming so there are significant emissions associated with its production. This is often referred to as “gray hydrogen.” In contrast, hydrogen produced using electrolysis and renewable energy is referred to as “green hydrogen” since there are no associated emissions.

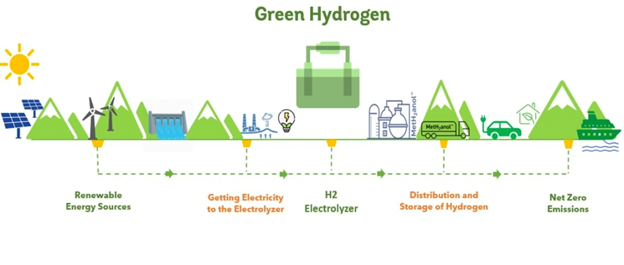

Utilizing hydrogen, particularly green hydrogen obtained via water electrolysis, is increasingly seen by policymakers and climate advocates as a key means to help migrate away from fossil fuels. In particular, green hydrogen’s growth is seen as a vital part of the global consensus goal of achieving “net zero” greenhouse gas emissions by 2050. The International Renewable Energy Agency forecasts that up to 12 percent of global energy use by 2050 will come from hydrogen in a “net zero” scenario.

The International Energy Agency noted in summarizing its Global Hydrogen Review 2022 report that the hydrogen industry is “expected [to undergo a] sixfold increase by 2025 in global manufacturing capacity of electrolysers” and could elevate its production from 290 gigawatts in 2030 compared to the 0.5 gigawatts it produced in 2021.

What Are the Hydrogen “Colors”?

It is important to note that there are more “colors” of hydrogen than just green and gray. Depending upon the production technique and the associated emissions, a range of colors can be assigned.

Green Hydrogen: The gold standard from a climate change mitigation standpoint, green hydrogen is created by using renewable energy (i.e., solar, wind, hydro) to run electrolyzers. PEM-Electrolyzers (the type that Plug focuses on) use that energy to split a water molecule, separating the H2 and the O. This results in a stream of gaseous hydrogen (H2) and a stream of gaseous oxygen (O2). Other methods of electrolysis do exist, namely, alkaline, AEM, and solid oxide. Each of these technologies has advantages and disadvantages and has a defined use case that it is most suitable for. Plug has chosen to focus on PEM technologies because we believe it is the most cost-effective, scalable, and versatile electrolytic production technique.

Our PEM electrolyzer technology will be used to construct North America’s first end-to-end green hydrogen production network, with an estimated 565 megawatts of product being installed across this network today at plants in Georgia, New York and Texas. More capacity looms in future phases. Globally, by 2025, Plug will have electrolyzer projects ranging from 1 megawatt to 1 gigawatt deployed across five continents.

For its progress in developing PEM hydrogen electrolyzers thus far, Plug received the top ranking from the consultancy Guidehouse Insights for hydrogen electrolyzer vendors in 2022.

Experts believe that green hydrogen is capable of powering at least 20% of the world. Driven by that belief, we are actively working to market our green hydrogen products to a wide range of customers worldwide.

The World Bank explained in June 2022 that globally there is an uptick in interest in green hydrogen “across multiple sectors including power generation, manufacturing processes in industries such as steelmaking and cement production, fuel cells for electric vehicles, heavy transport such as shipping, green ammonia production for fertilizers, cleaning products, refrigeration, and electricity grid stabilization.”

Plug can play a key role across multiple sectors because of the versatility of hydrogen and its unique position as a key decarbonization enabler in a wide range of industries. This breadth of application makes it easy to understand why there is a growing recognition about the future of green hydrogen.

Investment houses such as Goldman Sachs are also intrigued by the future potential of green hydrogen (and its ability to supplant grey hydrogen given falling prices), writing in a February 2022 equity research report that “Affordability is rapidly improving with green hydrogen likely to be at cost parity with grey in advantageous regions by 2025 and hydrogen cost parity with diesel in long-haul heavy road transport likely as early as 2027.”

Grey Hydrogen: By contrast, grey hydrogen is 72% of the global hydrogen production energy portfolio, according to WoodMackenzie. It is produced primarily via natural gas reforming (also known as steam reformation). It is the dominant form of hydrogen energy production today. The U.S. Energy Department notes that 95% of current global hydrogen energy production comes via this process which, simply put, involves cracking a natural gas/water mixture into hydrogen, carbon monoxide, and carbon dioxide.

Blue Hydrogen: Similar to grey hydrogen, blue hydrogen also utilizes natural gas as its feedstock in producing hydrogen via the steam reformation process. Unlike grey hydrogen, however, production units come equipped with carbon capture devices to reduce atmospheric methane or other greenhouse gas emissions. Blue hydrogen currently consists of 6% of global hydrogen production volumes, according to a study published by the academic journal “Energy Science & Engineering.” A key challenge with blue hydrogen production is what is done with the captured emissions. Generally speaking, sequestration projects have been demonstrated on a large scale with limited success.

Pink Hydrogen – Coming from neither renewable energy reserves nor fossil fuels, pink hydrogen is produced via nuclear energy as its input. It is also sometimes called purple hydrogen or red hydrogen.

What Are Plug’s Hydrogen Applications?

As the leader of the end-to-end green hydrogen ecosystem, Plug is capable of supporting customers from several industries. Plug’s customers include Amazon, BMW, The Southern Company, Carrefour, and Walmart. We have more than 180 hydrogen refueling stations deployed across the country today and more than 60,000 fuel cells in service with more than 1 billion operating hours in material handling.

However, Plug is very aware of the evolution of the hydrogen economy is well positioned to play a key role as a critical enabler. Plug’s green hydrogen portfolio and the application of Plug’s hydrogen touches aspects of the economy ranging from electricity production, hydrogen storage and transportation to market, on/off road mobility, green petrochemical manufacturing, and backup power generation.

As a case in point, Plus has installed hydrogen fuel cells at nearly 3,000 locations in 46 states within the U.S., as well as 34 countries on five continents.

Plug has several production plants in the works throughout North America. By 2025, we expect to produce 500 tons of green hydrogen. The number is expected to double by 2028 with an announced target of 1,000 tons.

Is Hydrogen Safe?

While some have noted hydrogen’s safety issues, nothing to be taken lightly, in reality hydrogen is no more dangerous than any fossil fuel used today.

The environmental advocacy group Natural Resources Defense Council, for example, points out that green hydrogen in particular “has been shown to be safer than conventional fuels in a multitude of aspects.” NRDC concludes this is the case because hydrogen spills or leaks do not pose a risk of environmental contamination ala fossil fuels for a number of reasons: differences in their gaseous forms; due to elemental lightness highlighted above, hydrogen rises and disperses more rapidly than fossil fuels such as gasoline and propane, which lowers the risk of harmful fires; and because gasoline has a higher explosivity risk than hydrogen when mixed in environments with oxygen.

The U.S. Department of Energy, for its part, agrees. The DOE’s Hydrogen and Fuel Cells Technologies Office states that “a number of hydrogen’s properties make it safer to handle and use than the fuels commonly used today,” including gasoline, natural gas, uranium, jet fuel, and diesel.

Hydrogen also has no higher of a leak risk to that of natural gas when placed in a pipeline, a 2020 study by University of California-Irvine researchers concluded.

Plug is an active member of the Center for Hydrogen Safety and has 25 years of experience in the hydrogen industry, carrying an excellent safety record. Our facilities are designed and built to the highest safety standards with automated leak and fire detection, isolation and shutoff with multiple redundant points of control, and we conduct several external-expert safety reviews of the design during the design-build process.

It is prudent to question the safety and toxicity of any fuel, not just hydrogen. The science says the contrary, as pointed out by both the U.S. Department of Energy and various scientific papers.

For more discussion on hydrogen safety issues, see our myth-busting article covering Hydrogen Safety 101. And if you’re ready to explore Plug’s global-leading hydrogen solutions, contact us!