From Grey to Green: How Refineries Can Turn to Plug for a Green Transition

All eyes are on oil companies to find ways to become carbon neutral, especially with the realization that the more than 1,000 oil refineries in the world contribute to at least 4% of the global carbon emissions.

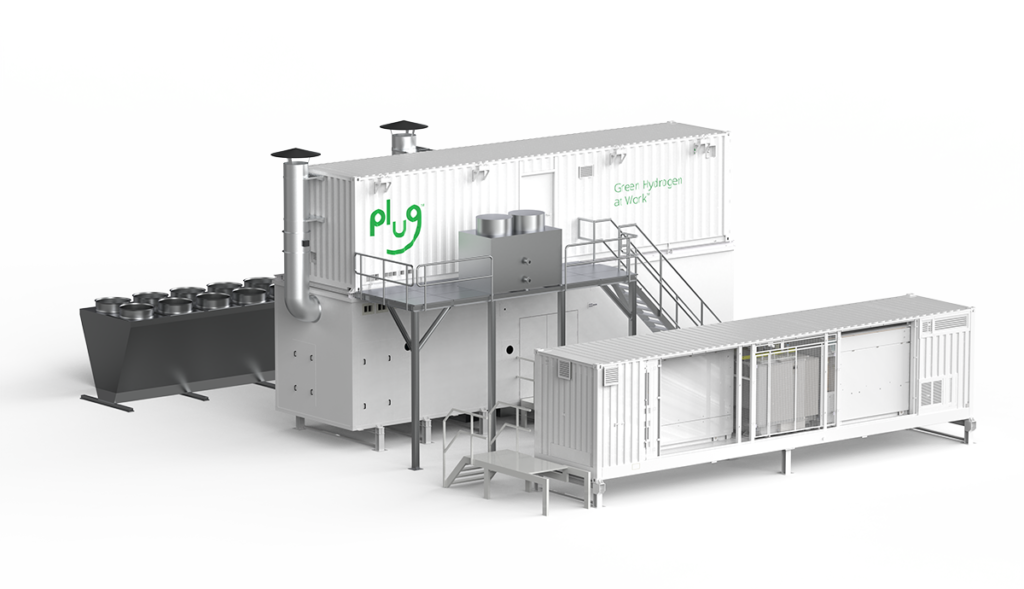

Leading the industry in finding environmentally friendly alternatives is Irving Oil, a Canada-based international energy company, that recently selected Plug to produce green hydrogen at one of its refineries using a 5-megawatt PEM electrolyzer, marking a significant milestone for the 100-year-old family operation.

Irving Oil, which has long been a producer of grey hydrogen, uses its Saint John refinery to produce 7% of all the hydrogen produced in Canada today. By shifting to green hydrogen, the refinery has the capability to produce 2 tons per day and ultimately reduce the amount of greenhouse gas emissions. The company has committed to working with Plug and other stakeholders to continue a shift to low-carbon hydrogen with the Plug electrolyzer as the first step. With grey hydrogen producing nine to 10 kilograms of carbon emissions per kilogram of hydrogen, the transition to up to 2 tons per day of green hydrogen can eliminate up to 6,500 tons of carbon emissions per year.

The steps taken by Irving Oil can easily be replicated by other leading refineries as Plug’s PEM electrolyzer team, which has nearly five decades of operational experience, has created systems that can be customized to meet individual customer needs.

Plug is a leading provider of turnkey hydrogen solutions for the global green hydrogen economy as business and government leaders work to decarbonize the planet. Aside from having a PEM electrolyzer team with nearly 50 years of industry experience, Plug can transport, store and dispense green hydrogen – and also produces products that allow industry to use that hydrogen. Andy Marsh, CEO for Plug, noted the Irving Oil commitment is the first step for the oil industry.

“Demand for green hydrogen is growing because companies that have relied on other forms of hydrogen are recognizing the viability of turning to green hydrogen to achieve net-zero carbon emissions,” Marsh said. “Driven by our leading electrolyzer technology and unparalleled manufacturing capacity, we are honored that Irving Oil has chosen Plug to support its initial investment in carbon-free hydrogen production and look forward to expanding the partnership.”

While grey hydrogen is produced from non-sustainable sources that release carbon emissions, green hydrogen is produced from renewable sources and only releases harmless oxygen. Entry into the green hydrogen industry establishes a commitment to reducing greenhouse gas emissions, strengthening decarbonization efforts and making an even more sustainable impact.

The green hydrogen that will be produced using Plug’s innovative PEM technology will power a number of industries, including mobility, and the refinery itself. Irving Oil also has plans to become the first hydrogen fueling infrastructure in Canada, while unlocking availability for regional customers, offering hydrogen for light- and heavy-duty vehicles as well as to tube trailers for delivery to customers. Investment in Plug’s electrolyzer technology is an important first step to any company expecting to shift its hydrogen production to low-carbon hydrogen over time.

“We are proud to build on our hydrogen production at our Saint John refinery, and work to develop new hydrogen production capabilities and grow a customer market,” Sarah Irving, Irving Oil Executive Vice President and Chief Brand Officer, said. “Staying true to the values that have guided our company for nearly 100 years, we are committed to taking concrete steps to evolve our business for the future, while providing the safe and reliable energy that people need.”

Plug’s 5-megawatt electrolyzer systems, including the one for the Saint John, New Brunswick refinery, are manufactured at Plug’s gigafactory in Rochester, N.Y., the world’s first and largest fuel cell and electrolyzer manufacturing gigafactory.

Want more details about Plug’s PEM team and technology? Let’s start the conversation today.