Fuel Cells vs. Batteries for Material Handling: Forklift Power, Activate!

Warehouses and distribution centers around the world require forklifts to function. They’re essentially the way goods move from one place to another. Without them, life as we know it would not exist. Food would rot in warehouses. Products would not make it to store shelves. Packages would be painfully slow to arrive at your door. In other words, forklifts —and their drivers— are essential to daily life.

For large-scale warehouse operations, there is a question to resolve as we move forward. Batteries or hydrogen fuel cells? What is the most effective way to power an electric forklift in a manner that optimizes productivity, efficiency, sustainability, and makes the most of warehouse space?

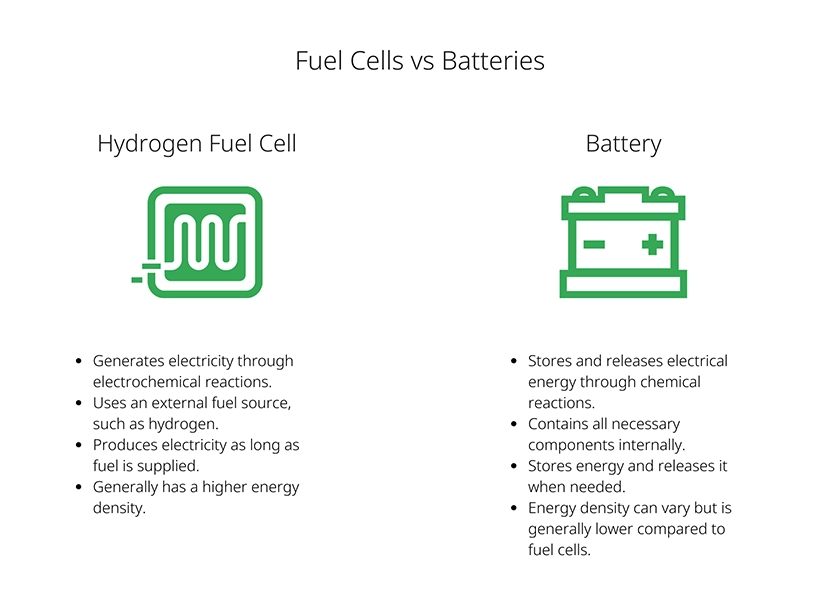

What’s the Difference Between Fuel Cells and Batteries?

A battery is a device that stores electrical energy in chemical form and converts it into electrical power when needed. It consists of one or more electrochemical cells, each comprising positive and negative electrodes separated by an electrolyte. During discharge, a chemical reaction occurs, releasing electrons that flow through an external circuit, producing electricity.

A hydrogen fuel cell is an electrochemical device that generates electrical energy through the reaction between hydrogen and oxygen, with water and heat as byproducts. In a fuel cell, hydrogen is fed to the anode and oxygen (usually from the air) to the cathode, separated by an electrolyte. The chemical reactions at each electrode produce electricity with the only emissions being clean water vapor.

What Types of Batteries Power Forklifts?

Lead-acid batteries are commonly used in forklifts and are known for their reliability and cost-effectiveness. These batteries employ a chemical reaction between lead dioxide and sponge lead in a sulfuric acid electrolyte to generate electrical energy. They are a popular choice for electric forklifts in various material handling operations. However, they have a relatively shorter lifespan and require regular maintenance, including watering and equalizing charges, to optimize performance.

Lithium-ion batteries have gained prominence in forklift applications due to their higher energy density, longer cycle life, and reduced maintenance requirements compared to lead-acid batteries. These batteries use lithium compounds as the electrode material and offer a lightweight and compact alternative, contributing to improved efficiency and maneuverability of electric forklifts. Lithium-ion batteries also provide faster charging times, allowing for increased uptime and operational flexibility.

What Types of Fuel Cells Power Forklifts?

Proton Exchange Membrane (PEM) fuel cells are commonly used to power forklifts. In a PEM fuel cell, hydrogen is supplied to the anode and oxygen from the air to the cathode, separated by a proton-conducting membrane. The chemical reactions at the electrodes produce electricity, water, and heat. PEM fuel cells are particularly well-suited for forklifts due to their ability to operate at relatively low temperatures and respond quickly to changes in power demand. This makes them efficient and practical for the stop-and-start nature of forklift operations, as they can provide on-demand power with high responsiveness.

Solid Oxide Fuel Cell (SOFC) operate at higher temperatures compared to PEM fuel cells and use a solid oxide electrolyte. They are advantageous for their high efficiency and ability to directly convert a variety of fuels into electricity. While not as common as PEM fuel cells in forklift applications, SOFCs offer the potential for greater fuel flexibility and could become more prevalent in certain industrial settings where their specific characteristics are advantageous.

Which is Better for Material Handling? Fuel Cells or Batteries?

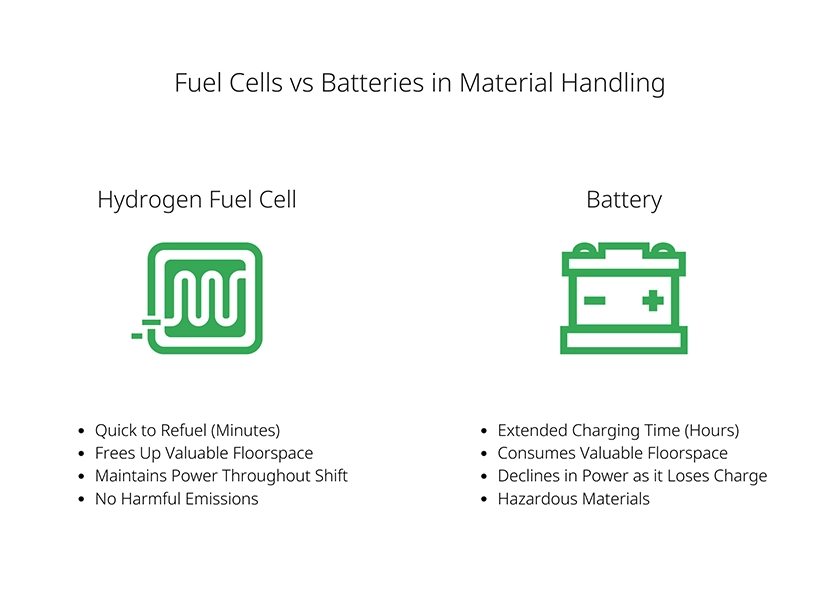

PEM fuel cells and batteries are both useful technologies for material handling, but each has distinct characteristics that make them suitable for different applications. While batteries store and release electrical energy through a reversible electrochemical reaction, PEM fuel cells generate electricity by combining hydrogen and oxygen, producing water and heat as byproducts. In material handling, particularly in industries requiring heavy-duty and prolonged operations, PEM fuel cells offer several advantages over traditional batteries.

One significant advantage of PEM fuel cells is their faster refueling time compared to a battery’s recharging or swapping time. In material handling operations, downtime is a critical factor, and the refueling capability of PEM fuel cells of under three minutes enables continuous workflow without extended breaks for recharging. Additionally, PEM fuel cells provide a consistent power output throughout their operation, avoiding the gradual decline in performance commonly seen in batteries.

This consistent power delivery is especially beneficial in applications where sustained power is essential for efficient material handling, contributing to increased productivity and operational efficiency. Overall, while both technologies have their merits, the faster refueling and consistent power output of PEM fuel cells make them a compelling choice for material handling applications, ensuring seamless and efficient operations.

What Type of Infrastructure is Required for Batteries vs. Fuel Cells?

The footprint of battery charging stations versus fuel cell refueling stations is a critical consideration when deciding between the two. Traditional battery charging stations often require dedicated spaces within the warehouse, consuming valuable square footage that could otherwise be employed in revenue-generating activities. The need for designated charging areas not only consumes space but also limits the flexibility of warehouse layout and design.

On the other hand, fuel cell refueling stations present a distinct advantage by freeing up valuable warehouse real estate. The compact nature of fuel cell infrastructure allows for greater flexibility in warehouse design, enabling companies to optimize their spatial configurations for maximum efficiency and revenue generation. This liberated space can be repurposed for additional storage, expanded operational areas, or streamlined workflows, thereby contributing to a more agile and profitable material handling ecosystem.

What’s more Lithium-ion batteries depend on power from the electric grid, which is centralized within the warehouse and often can’t provide enough power for a fleet of forklifts, and as the fleet grows the drawbacks become more pronounced. This does not happen with hydrogen fuel cells which operate independent of any grid system.

What are the Environmental Impacts of Batteries vs. Hydrogen Fuel Cells?

Battery-powered forklifts raise environmental concerns due to the production, use, and disposal of battery components. The manufacturing of batteries involves the extraction and processing of raw materials, including metals like lithium, cobalt, and nickel, which can lead to habitat destruction, resource depletion, and environmental pollution. What’s more, the energy-intensive production processes contribute to a significant carbon footprint. During operation, batteries for forklifts require electricity for charging, which may come from fossil fuel-dependent power sources, further exacerbating their indirect environmental impact.

Finally, the disposal of used batteries poses challenges, as they contain hazardous materials that can harm ecosystems if not handled properly. While efforts are made to improve battery recycling, the ecological footprint of traditional forklift batteries remains a concern in terms of both production and end-of-life management.

Hydrogen fuel cells offer a more environmentally friendly alternative for forklifts. The production of hydrogen can employ renewable energy sources, such as wind or solar power, minimizing the carbon footprint associated with fuel cell technology. When hydrogen is used in fuel cells to power forklifts, the only byproducts are water vapor and heat, resulting in zero emissions of harmful pollutants during operation.

At the end of a fuel cell’s life, the recyclability of its components is relatively straightforward, contributing to a more sustainable life cycle. The adoption of hydrogen fuel cells in material handling can play a role in reducing the ecological impact associated with traditional battery technologies, aligning with the broader goal of achieving environmentally responsible corporate practices.

What are maintenance concerns for batteries vs fuel cells?

Maintaining batteries in forklifts involves regular checks on electrolyte levels, water refilling for lead-acid batteries, and monitoring for signs of corrosion. Battery charging also requires careful management to prevent overcharging, which can significantly impact the lifespan of the battery. Scheduled maintenance, such as equalizing charges and conducting capacity tests, is essential to ensure optimal performance. What’s more, batteries may experience a gradual decline in efficiency over time, leading to reduced runtimes and overall productivity. Replacement of battery cells or the entire battery pack becomes necessary at the end of their life cycle, contributing to both operational downtime and additional costs.

Fuel cells in forklifts generally require less maintenance compared to batteries. The primary maintenance tasks involve periodic inspection of the fuel cell stack for signs of wear and tear, as well as ensuring that the hydrogen supply system remains free of contaminants. Fuel cells have fewer moving parts, reducing the likelihood of mechanical failures. While the initial investment in fuel cell technology may be higher, the potential for lower maintenance costs and increased operational uptime can offset these expenses over the long term.

For large-scale warehouse operations, there really is no question. Fuel cells win over batteries in productivity, efficiency, sustainability and use of warehouse space for revenue-producing activities.

For more information about hydrogen fuel cells vs batteries in forklifts, check out these eBooks and blog posts:

Fueling the Future of Material Handling

Hydrogen Fuel Cells Advantages over Li-ion Batteries for Material Handling Applications

Leading the Charge: How a Fuel Cell Compares to a Lead-Acid Battery