Harnessing the Power of Plug’s Liquefaction Technology

As the company behind the end-to-end green hydrogen ecosystem, Plug has spearheaded green hydrogen’s global growth, alongside fuel cells and electrolyzer technology, becoming a vertically integrated sector powerhouse.

As countries transition from fossil fuels to renewable energy sources under global climate goals, the wide-ranging applications of fuel cells within multiple sectors have lifted hydrogen’s profile as crucial for realizing government and corporate sustainability plans. Yet the ledger from hot prospect to robust reality, creating a method for transporting hydrogen to targeted markets must transpire.

And that’s where Plug comes into play.

To move hydrogen over long distances from Point A to Point B, liquefaction of the molecules — super-chilling the gas at -253°C into a more compact, mass marketable liquid fuel — must happen. Hydrogen liquefaction, in the years to come, could resemble that of natural gas liquefaction — also known as liquefied natural gas, or LNG. In other words, building terminals turning hydrogen into a containerized fuel that can globe trot as LH2 (liquefied hydrogen), just as LNG has upended the global energy landscape in the past decade.

Plug’s leadership in engineering and selling hydrogen liquefiers can assist countries and companies rapidly increasing uptake of a fuel source seen as strategically important for greening tough to decarbonize sectors. The International Energy Agency has pointed to green hydrogen as needing a 300-fold increase in output to achieve “net zero” greenhouse gas emissions goals by 2050.

Working Principles of Plug’s Liquefaction Technology

Plug’s hydrogen liquefaction process resembles the super-chilling technique used to yield LNG. In liquefying green hydrogen, it can be carried throughout domestic corridors across our home country in the U.S. via both pipelines and liquid hydrogen tankers carried upon trucks. Worldwide, hydrogen liquefaction can also enable carriage within liquid organic hydrogen carriers (LOHC), modeled after LNG supertankers.

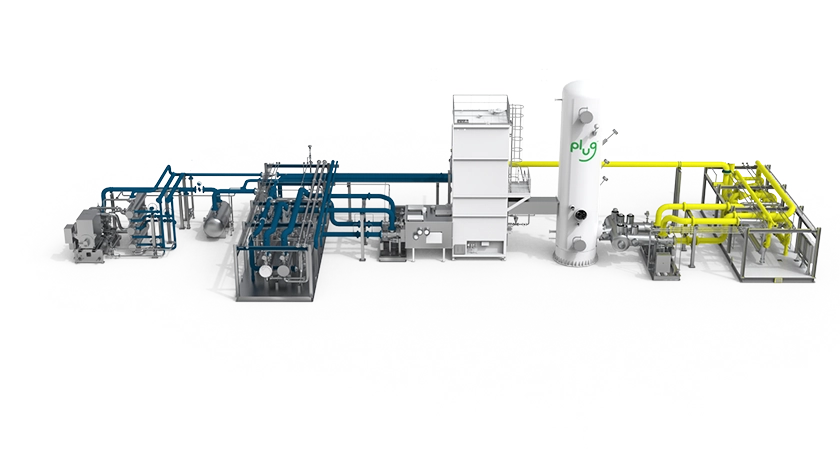

To minimize energy loss of hydrogen as it moves from starting to end point, Plug’s engineers have collaborated with suppliers to streamline the product’s movement. Relatedly, Plug has designed its hydrogen liquefaction plants — coming in both 15 and 30 tons per day configurations — to operate over a wide ambient temperature ranges while avoiding hydrogen loss in transporting the product to market.

The video below offers a visually interactive depiction of how Plug’s liquefiers function.

Another example of Plug’s cutting-edge hydrogen liquefaction technology: while competitors require eight green hydrogen tube trailers for every 520 kilograms of the resource shipped, Plug’s LH2 tankers can ship nearly nine times the amount of the green hydrogen to market for each individual shipment. This leads to both fewer shipments and operational money saved, which when combined with other cost-savings via less energy shrinkage, also lowers capital expenditures for our project partners.

Plug’s hydrogen liquefiers increase cash flow to our partners in maximizing green hydrogen utilized to bolster climate and sustainability goals.

Benefits of Plug’s Liquefaction Technology

Included in the Inflation Reduction Act in 2022 was legislation creating a $3 per kilogram production tax credit for green hydrogen. It has created a bull market for liquefying and selling the fuel domestically and globally. Green hydrogen, under this new paradigm, now sits as cost-competitive with both gray hydrogen and diesel.

Under this newly infused economic terrain, bold action from industry leaders will help super-scale superchilling hydrogen liquefaction technology, alongside building midstream and downstream technology required for the wide-ranging adoption needed to meet global climate and sustainability goals.

Aside from the climate and sustainability imperatives presaging a path to and premise propelling passage of the Inflation Reduction Act, embodying the rationale behind the broader worldwide push to increase the technology’s nameplate capacity, great economic benefits could simultaneously accompany this climate-driven effort.

The Hydrogen Council concluded that worldwide, hydrogen’s global burgeoning could create “30 million jobs by 2050, and a $2.5 trillion annual revenue boost to economies worldwide.” And in the U.S., a 2021 McKinsey & Company study estimated that by 2030, the hydrogen sector’s growth could spawn 700,000 jobs.

Applications of Plug’s Liquefaction Technology

Comprehending the massive economic opportunity that liquefying hydrogen provides, Plug has forged ties with a number of partners, demonstrating use cases for Plug’s liquefaction technology.

In late-2022, Nikola — a company focused on manufacturing both fuel cell and battery electric vehicles, with a focus on trucks — announced a Green Hydrogen Supply Agreement that will ramp up to 125 tons of green hydrogen delivered per day from Plug to Nikola. The Agreement will include a 30 tons per day hydrogen liquefaction system at Nikola’s Arizona hydrogen hub, eventually slated for a production capacity of 150 tons per day.

And most recently, Plug formed a partnership with TC Energy to design and deliver two 30 ton-per-day liquefiers to a partner company best known for its North America-wide gas pipelines network, currently attempting to green its energy portfolio.

Broadly, Plug CEO Andy Marsh explained in a 2022 call with investors that “We are a real believer that during the next 10 years, liquid hydrogen is going to be the primary most cost-effective means of transporting hydrogen any distances.”

The partnerships formed so far and the value they will create, then, only presses play on Plug’s hydrogen liquefaction proliferation prelude.

Hydrogen Liquefaction Growing

Hydrogen liquefaction will ensure green hydrogen grows in a way similar to natural gas’ rise over the past decades. The ability to liquefy the fuel serves as a compulsory first step toward realizing the benefits of fuel fuels, their efficiency, and their numerous applications.

Plug is building green hydrogen production plants to produce 500 tons daily by 2025 — enough to ensure fuel supply to our customers and then some.

While an ambitious goal at face-value, 1,000 tons per day equates to 10,000 Class 8 trucks or 600 megawatts of stationary backup power of hydrogen fuel cells. A great starting point for sure, but also only a harbinger of far more to come.

To learn more about Plug’s liquefaction technology, please check out our white paper and our liquefier technological specifications materials. And for a more interactive discussion on these matters, please check this recent podcast interview on H2Tech with Sanjay Shrestha, Chief Strategy Officer for Plug, focused on our liquefaction technology’s present and future.

And if you’re intrigued with what you see, please contact us to learn more about our custom-fit solutions for your hydrogen liquefaction needs.