Hydrogen Fuel Cell Forklifts: The Impact of Fuel Cells in Material Handling

Hydrogen fuel cell technology is revolutionizing the material handling industry. By using hydrogen to generate clean energy, these fuel cells power electric forklifts (often referred to as lift trucks or forklift trucks) with zero emissions, making them a sustainable alternative to traditional forklifts.

The demand for efficient and sustainable solutions in the material handling industry is growing rapidly. Companies are increasingly looking for ways to increase their operational efficiency while also reducing their environmental impact. Hydrogen fuel cell forklifts meet this need perfectly, offering a green solution that doesn’t compromise on performance.

Plug has been leading the charge in this field since 2007. We began designing and building hydrogen fuel cells specifically for material handling applications, and we’ve continued to innovate and expand our offerings ever since. Our hydrogen fuel cells seamlessly replace batteries in electric forklift trucks, providing an efficient, cost-effective, and eco-friendly alternative.

Can Forklift Trucks Run on Hydrogen?

Absolutely! Forklift trucks can efficiently operate using hydrogen fuel cells, and it’s a game-changer for industry. But how does it all work?

Hydrogen fuel cells generate electricity through a chemical reaction between hydrogen and oxygen. When hydrogen gas enters the fuel cell, it reacts with oxygen from the air. This reaction produces electricity, water, and heat. The electricity is then used to power the forklift truck, enabling it to perform material handling tasks just like any traditional forklift truck.

The beauty of hydrogen fuel cells is their versatility. They can be used in various types of forklifts, whether it’s a small electric pallet jack or a larger heavy-duty stand-up truck. This compatibility makes hydrogen fuel cells a viable option for different warehouse and distribution center operations.

Not only do hydrogen fuel cells provide consistent power, but they also offer quick refueling times. Instead of waiting hours for a battery to charge, a hydrogen fuel cell forklift can be refueled in just a few minutes, like refueling a car. This leads to less downtime and more productivity on the warehouse floor.

In short, hydrogen fuel cells make forklifts more efficient, versatile, and eco-friendly, making them an excellent choice for modern material handling needs.

The Advantage of Hydrogen Fuel Cell Forklifts

Hydrogen fuel cell forklifts come with a host of benefits that make them stand out in the material handling industry. Let’s dive into some of the key advantages.

Hydrogen fuel cell forklifts can be refueled in just a few minutes, much faster than the hours it takes to charge a traditional battery. This quick refueling time leads to increased productivity and less downtime.

Plus, hydrogen fuel cells provide consistent power output, ensuring that forklifts maintain optimal performance throughout their operation, enabling more picks per hour.

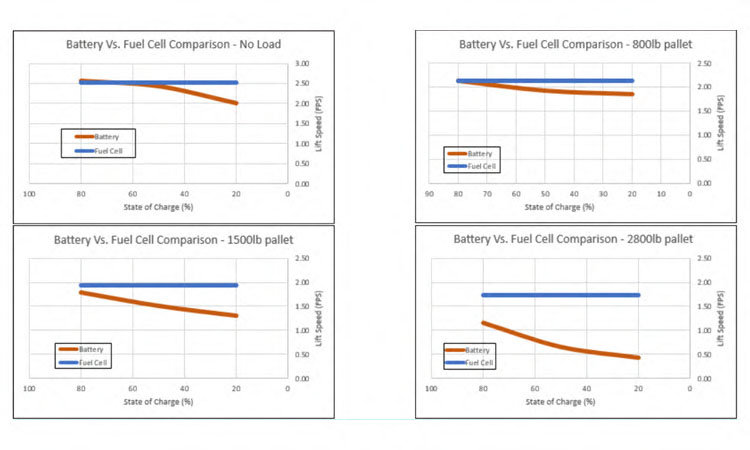

Here’s a visual that compares the lift speed of battery-powered forklift trucks versus hydrogen fuel cell forklift trucks:

As the visual shows, hydrogen fuel cells maintain consistent lift speed across various loads, even as the state of charge decreases. This consistent performance is a significant advantage over traditional batteries.

Additionally, hydrogen fuel cell forklifts require less maintenance compared to battery-powered forklifts. The fuel cell system has fewer moving parts, resulting in reduced wear and tear and lower maintenance costs. This translates to fewer disruptions and more reliable operations.

Overall, the combination of efficiency, reduced maintenance, and sustainability makes hydrogen fuel cell forklifts an excellent choice for modern warehouses and distribution centers.

The Cost Considerations of Hydrogen Forklifts

When it comes to new construction sites, known as greenfields, hydrogen forklifts have a distinct advantage. Unlike traditional electric forklifts, hydrogen fuel cell forklifts do not require extensive electric infrastructure. Building such infrastructure can be incredibly costly and often involves long delays. By opting for hydrogen fuel cells, companies can bypass these challenges, saving both time and money from the start.

From an investment perspective, transitioning to hydrogen fuel cell forklifts involves several cost considerations. Specific cost breakdown and savings will vary depending on factors such as operational requirements, energy consumption, and location. While the initial investment might be higher compared to traditional forklifts, it’s important to look at the bigger picture.

Hydrogen fuel cells contribute to increased efficiency and productivity. Faster refueling times mean forklifts spend more time in operation and less time out of service. This increased uptime directly translates to higher productivity and, ultimately, better financial performance for the business.

Additionally, battery charging infrastructure takes up valuable warehouse space that could otherwise be used for profit-generating activity. There are several advantages that hydrogen fuel dispensers have compared to battery chargers: they are small in size, flexible in placement, and fast to fuel. This allows facilities using fuel cell lift trucks to maximize their revenue generating space.

When evaluating the total cost of ownership, it’s essential to weigh the benefits of hydrogen fuel cell forklifts against the initial investment. The potential for reduced maintenance costs, combined with the efficiency gains and reclaimed space, often make hydrogen forklifts a financially sound choice over time. By considering these factors, businesses can make informed decisions that align with their long-term operational and financial goals.

The Scope and Growth of the Hydrogen Forklift Market

The adoption of hydrogen fuel cell forklifts is rapidly increasing across various industries. This growth is driven by the rising demand for more sustainable and efficient material handling solutions. Companies are increasingly recognizing the benefits of hydrogen fuel cells and are integrating them into their operations to reduce their environmental footprint while enhancing efficiency.

Several factors contribute to the expansion of the hydrogen forklift market. One key factor is the continuous advancements in hydrogen fuel cell technology. These innovations are making fuel cells more efficient, reliable, and cost-effective, making them a viable option for a wide range of applications.

Another significant factor is the push for green logistics. As businesses strive to adopt more eco-friendly practices, hydrogen fuel cell forklifts present an attractive solution. They help companies meet their sustainability goals by offering zero-emission operations, which is increasingly important in today’s environmentally conscious market.

Supportive policies and regulations aimed at reducing carbon emissions in industrial operations are also playing a crucial role in market growth. Governments and regulatory bodies are promoting the use of clean energy solutions, including hydrogen fuel cells, through incentives and supportive frameworks. These policies encourage businesses to invest in hydrogen technology, further driving market adoption.

Looking ahead, the market potential for hydrogen fuel cell forklift trucks is vast. Ongoing technological innovations continue to improve the performance and affordability of fuel cells. Additionally, the growing consensus on the need for environmental sustainability in logistics and supply chain management ensures that hydrogen fuel cell forklifts will play a significant role in the future of material handling.

Manufacturers of Hydrogen Powered Forklifts

When it comes to hydrogen-powered forklifts, Plug stands out as a leading technology provider in the industry. Since 2007, Plug has been at the forefront of hydrogen fuel cell technology, specifically tailored for material handling applications. Our commitment to advancing this technology has resulted in reliable, efficient, and sustainable solutions that power forklifts in warehouses and distribution centers worldwide.

Companies like Toyota, Hyster-Yale, and Linde are making significant strides in this space, offering a variety of hydrogen-powered forklifts to meet diverse operational needs. These manufacturers are helping to expand the market and drive innovation, ensuring that businesses have access to the best possible solutions.

At Plug, our dedication to advancing hydrogen fuel cell technology is unwavering. We continually invest in research and development to create cutting-edge solutions that address the evolving needs of the material handling industry. Our comprehensive offerings include not just the fuel cells themselves but also the necessary infrastructure for hydrogen production, storage, and refueling. This end-to-end approach simplifies the transition to hydrogen fuel cells for our customers, allowing them to focus on their core operations without worrying about the complexities of the new technology.

By leading the charge in hydrogen fuel cell technology, Plug is helping to shape the future of material handling, making it more sustainable, efficient, and forward-thinking.

Conclusion

Hydrogen fuel cell forklift trucks represent a significant leap forward in the material handling industry. They offer a sustainable, efficient, and reliable alternative to traditional forklifts, addressing the growing need for greener operations. With quick refueling times, consistent power output, and reduced maintenance needs, fuel cell powered forklifts enhance productivity and operational efficiency.

Plug has been a pioneer in this field, providing comprehensive solutions that include fuel cells, hydrogen production, storage, and refueling infrastructure. Alongside other industry leaders, Plug continues to innovate and expand the possibilities for hydrogen-powered material handling.

By embracing hydrogen fuel cell technology, companies can not only improve their operational efficiency but also make a meaningful contribution to environmental sustainability. The future of material handling is here, and it’s powered by hydrogen.

For more detailed information and insights, check out some of our fuel cells for material handling resources.