Hydrogen Fuel Cells in Retail Material Handling

The retail industry saw the value of hydrogen fuel cells early and quickly adopted them in their distribution centers to meet their sustainability goals.

But the benefits didn’t stop and just greening their operations. With lead-acid batteries powering their distribution center forklifts, companies had to give up valuable floor space for storage, charging, and mid-shift battery swaps. They also had to contend with declining operator productivity as batteries lost their charge and they had to leave the floor for replacements. What’s more, lead-acid batteries presented safety risks and sustainability challenges that could not be otherwise solved.

Like many companies across different industries, customer demand for greener operations has been an influential factor in the decision to go green. Walmart and Home Depot were among the first retailers to move to fuel cell-powered forklifts, establishing them as sustainability leaders and setting an influential precedent for other sectors. But what started as a green effort, soon became a business decision. They simply could get more work done more efficiently.

Other industries have taken note, realizing the potential for similar benefits by embracing hydrogen fuel cells, further propelling the expansion and development of this green technology as companies across the board seek to emulate the success achieved by the early adopters.

Hydrogen Fuel Cell Case Study: Walmart

Walmart is a retail corporation that operates a chain which includes Walmart Supercenters, Sam’s Club and Walmart Neighborhood Markets. Walmart’s network of more than 150 distribution centers has proven to be a competitive advantage in the support of their retail operations.

The Walmart supply chain network consists of distribution centers in various configurations to support specific types of retail business. Walmart’s distribution footprint includes more than 120 million square feet of distribution space in configurations that range from 20°F Freezers to ambient temperature.

Walmart distribution centers typically support more than 100 stores in a 150-mile radius. Walmart’s fulfillment centers are strategically located to give them very quick and highly efficient access to consumers.

Situation: Walmart has used hydrogen fuel cell-powered forklifts since 2012 and currently operates more than 10,000 fuel cell units across many distribution and fulfilment centers. Walmart’s focus on sustainability drove its interest in fuel cells. The company began its sustainability efforts in 2005 and has since significantly grown its efforts.

Plug Solution: After Walmart ran a series of fuel cell trials, it became apparent that fuel cells offered significant productivity gains in its operations with zero harmful emissions.

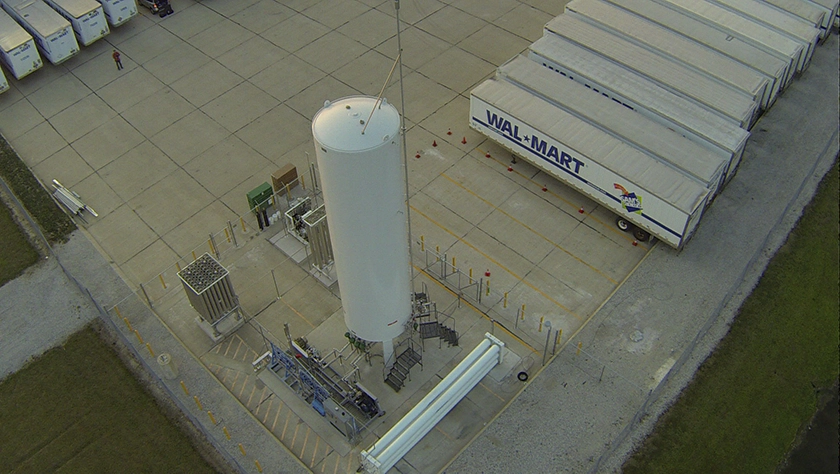

Plug currently provides Walmart with end-to-end hydrogen solutions that include hydrogen fuel cells, fuel, and maintenance services for all the forklifts and hydrogen installations at various Walmart distribution centers across the US.

The fuel cells can operate in forklifts at sub-zero temperatures and have been shown to improve sustainability and productivity significantly compared to alternate grid-powered battery solutions.

Key Results: Significant improvement in warehouse space savings, electricity consumption, operator and equipment productivity and sustainability.

Further Engagement: Since 2012, Plug has installed more than 10,000 fuel cell units for Walmart’s forklift operations. What is more, in 2022, Plug and Walmart announced an agreement for an option to deliver up to 20 tons per day of liquid green hydrogen to power material handling lift trucks across Walmart’s US distribution and fulfillment centers.

Walmart Customer Testimonials

“The challenges [of COVID-19] have increased demand for leading brands providing necessary goods and services to customers. At our distribution facilities across the country, our decision to be an early adopter of Plug Power’s hydrogen fuel cells has helped us manage and meet the increased demand for food and basic supplies. This is why we’re excited to expand Plug Power’s proven solutions into our eCommerce network in 2021.”

-Senior Director Walmart Supply Chain

“Hydrogen is critical to helping us power a more sustainable supply chain and Plug Power’s hydrogen solutions allow us to continue making progress. Sourcing green hydrogen can help bring Walmart closer to reaching our goal of zero emissions by 2040.”

–Senior Director of Supply Chain Maintenance Services

This case study is drawn from Plug’s ebook, Implementing Fuel Cells in Material Handling: Learning from Leaders.