It’s not magic; it’s a by-product of Plug Power’s fuel cells!

Tags: fuel cell water

“If there is magic on this planet, it is contained in water.” Loren Eiseley*

When Plug Power usually talks about our fuel cell products, we discuss the productivity, reliability, and efficiency gains seen by customers who use our clean power products for their automotive fleets, material handling, and backup power needs. We talk about sustainability in terms of emissions reduction and cleaner facilities, which no longer use batteries that need to be swapped and charged, combustion engines, or diesel generators that pollute the air. We don’t normally talk about fuel cell water. But water is a by-product of all of Plug Power’s fuel cells – and all proton exchange membrane (PEM) fuel cells regardless of manufacturer. It turns out that, whether we talk about it or not, water has an important place in our customers’ operations now – and can be used for much more with a little innovation.

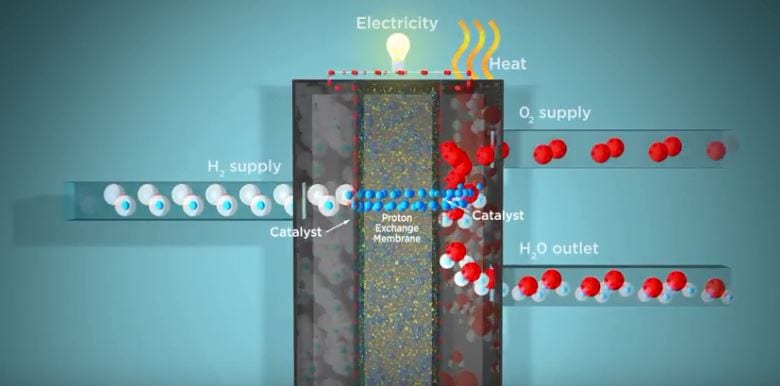

Where does the water come from? The basic science behind fuel cell water production is in the special PEM membrane inside each fuel cell. Hydrogen enters one side, oxygen from the air around us from the other. They interact with the membrane, which extracts electricity from the hydrogen electrons, sending the protons across the membrane to meet up with the oxygen, forming clean, deionized water, as seen in this video.

That water has to go somewhere. A portion of it is used by the fuel cell to ensure an optimum state of hydration, allowing it to function as efficiently as possible. In our air-cooled stacks, used in series 3 material handling fuel cells (GenDrive) and all of our stationary power products (GenSure), the water produced is almost completely consumed. The remainder is exhausted as a very small amount of water vapor.

In our GenDrive fuel cells for class 1 & 2 material handling vehicles as well as our motive ProGen fuel cells, all of which are liquid-cooled, the excess water is collected each time the fuel cell visits the hydrogen fill station. From there, it becomes available to be used at the customer facility or handled as waste water.

How much water is that? It averages out at 0.75 liters of water per kilowatt-hour of runtime for our forklift fuel cells. For a fleet using 55 Class 1 forktrucks for 175 kWh per week, that’s just short of 2,000 gallons of water each week. For an operation using 19 Class 2 forklifts for 78 kWh per week, that’s about 300 gallons of water each week. Most facilities use a mix of equipment, with the percentages designed to their individual needs.

“Water is the foundation of our economies, communities, ecosystems, and quality of life.” Kate Brown, Governor of Oregon

What can the water be used for? A number of Plug Power customers understand the value of fuel cell water and already use it within their own facilities for some impressive functions. Others have begun to envision what they could do in the future.

- Floor Scrubbers: It’s not too hard to imagine how dirty the floors get in a 24×7 distribution or manufacturing facility. That’s where floor scrubbing machines come in. Most facilities have them and they come in a variety of sizes. One such machine holds up to 100 gallons of water in its reservoir for a trip of up to 100,000 square feet of floor space. With facilities ranging from several hundred thousand to over one million square feet, that fuel cell water can be put to good use!

- Windshield Wiper Fluid: Material handling facilities have large delivery trucks driving in and out on a continual basis. And fleets like FedEx, using ProGen-powered fuel cell electric delivery vans, visit hydrogen fueling stations daily. The deionized water from the fuel cell is being used by some to fill the windshield wiper reservoirs of these large trucks, keeping their drivers safer on the dirty streets they drive.

- Landscape hydration: Plants need water. Fuel cells provide clean water. It’s a match made in…well…science.

- Manufacturing: A number of manufacturing processes use water as a cooling or cleaning agent. And some Plug Power customers are considering how they can decrease their reliance on city water by diverting fuel cell waste water into their systems.

- LEED Certification Data: Two Plug Power GenDrive customers, Golden State Foods and a major candy manufacturer, have achieved LEED Gold Certification based, in part, on their use of fuel cells and the resulting water within their facilities, which reduces their use of city water.

Progress with corporate efficiency and sustainability is about being forward-looking and thinking outside the box – er, fuel cell. As fuel cells are used by more and more organizations, the possibilities continue to grow. Clean power – check. Clean fuel – check. Clean water – check.

#InfiniteDrive

*Loren Eiseley was an American anthropologist, educator, philosopher, and natural science writer, who taught and published books from the 1950s through the 1970s.