Plug Electrolyzers: The Future of Low-Carbon Methanol Production

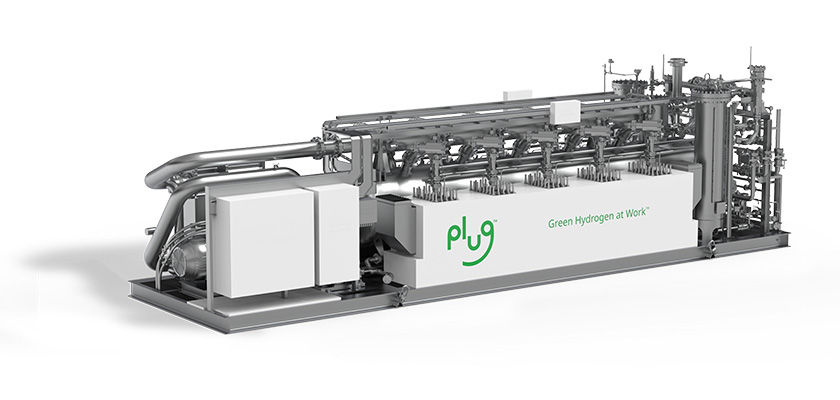

Electrolyzers serve as a fundamental component of Plug’s green hydrogen system and the overall production of green energy. Plug has been designated a global leader in electrolyzer technology and is a leading global supplier with companies relying on Plug’s team with five decades of experience.

Plug’s electrolyzers can — among other applications — produce low-carbon methanol, also known as green methanol. Green methanol, akin to green hydrogen, takes what has been a traditionally fossil fuel-feedstock energy resource and uses renewable fuels like green hydrogen within its chemical mix to lower its greenhouse gas emissions footprint.

When produced via wood-based biofuels, the most common type of low-carbon methanol, the International Energy Agency explains that for greenhouse emissions it can achieve “reduction potentials…competitive [with] established renewable fuels.”

This only pertains to the climate science for methanol’s insertion into internal combustion engines, however, unrelated to its production. But as a non-combustion technology, water electrolyzers can also both green the methanol production process itself and the manufacturing of methanol-based end-products.

Plug Electrolyzers: How They Work

So what’s an electrolyzer anyway? Plug’s (proton exchange membrane) PEM stacks enable the water electrolysis process, which utilizes electricity – mainly renewable – to split water into hydrogen and oxygen. That hydrogen is then captured for a wide range of applications Plug has taken the lead in deploying. For more on how an electrolyzer works scientifically at a 101 level, see our video below.

Electrolyzers, as non-emitting technology, stave off greenhouse gas and co-pollutant emissions. They are also versatile, ably utilizing a variety of energy inputs ranging from wind, solar hydroelectric power, or biofuels in producing zero-carbon green hydrogen.

It is here that green methanol comes into play. Currently sitting at only .2% of global methanol consumption, utilizing electrolyzers to produce green methanol could lower the current emissions output associated with carbon-intensive chemical production feedstocks and in areas such as marine transportation.

Three types of green methanol production techniques currently exist: Traditional methanol, e-methanol, and biomethanol.

Traditional methanol, as the name implies, produces conventional fossil-fuel based methanol (predominantly from natural gas) but intakes green hydrogen as the fuel source to make the production process more climate-friendly (i.e. green methanol).

E-methanol, by contrast, utilizes hydrogen combined with CO2 obtained via the bioenergy with carbon capture and storage (BECCS) or Direct Air Capture (DAC). Intaking the CO2 from non-fossil fuel sources, the electrofuel (hence e-fuel) produced is a lower carbon methanol end-product.

Lastly, biomethanol intakes primarily wood-based biofuels as its feedstock, combined with green hydrogen for a carbon neutral or even carbon negative end-product.

Plug’s electrolyzers, and the water electrolysis process they utilize in being powered by renewable energy, stand ready to assist in all three production processes. For more on the trio, see our white paper on electrolyzers and low-carbon methanol.

And as a related decarbonization benefit, the excess supply of green hydrogen utilized during electrolysis within Plug’s electrolyzers can also be used in other parts of the process supply chain, also helping to cut energy procurement costs.

Benefits of Low-Carbon Methanol Production

Methanol, as a feedstock product, is often used as a solvent, antifreeze, and within the synthetic fuels production processes, while also sometimes utilized for mobility purposes.

Compared to using gasoline, even conventional fossil fuel-based methanol has a “greenhouse gas emission benefit over gasoline,” according to the International Energy Agency. Methanol of all types also has air quality benefits compared to gasoline, reducing nitrogen oxide (NOx) and sulfur oxide (SOx) emissions. At the end of the day, albeit, methanol from fossil fuels still relies on fossil fuels in need of phasing out under global climate goals, unleashing .3 gigatons of CO2 into the atmosphere under the status quo.

Green methanol, by contrast, can curtail emissions portfolios. When made from forest residue, for example, it can cut greenhouse gas emissions from 38% to 165% compared to traditional shipping fuels or fossil fuel-based methanol.

Further, methanol is an advantageously energy dense fuel when used within hydrogen fuel cells, “packing more hydrogen in this simple alcohol molecule than can be found in hydrogen that’s been compressed (350-700 bar) or liquified (-253˚C),” according to the Methanol Institute.

Given these perks, the International Renewable Energy Agency (IRENA) concluded in 2021 that global demand for methanol is expected to rise in light of global climate policy and sustainable business practice imperatives, from 120 million metric tons in 2025 to 500 million tons by 2050. The vast bulk of this growth, IRENA projects, will come from green methanol.

The methanol industry is already a major economic engine, as well, creating over $55 billion in economic activity per year and over 90,000 jobs, according to the Methanol Institute. Great potential exists for even further growth on both fronts as green methanol grows from infant to mature adult.

Reducing Greenhouse Gas Emissions

Many use cases exist for deploying green methanol made within Plug’s electrolyzers as a means of lowering greenhouse gas emissions and air quality footprints.

In areas such as transportation, as IRENA notes, “renewable methanol offers carbon reduction benefits ranging from 65% to 95%” drops in the sector. The Methanol Institute, too, points out that for stationary purposes — given the intermittent nature of solar and wind — green methanol could be built into the grid and fed into electricity production to ensure a completely renewable energy electricity portfolio, even amid intermittency.

At-large, the multiple ways Plug’s electrolyzers can interplay with green methanol depicts CEO Andy Marsh’s explanation of green hydrogen as “the Swiss Army knife of this transition to renewable energy.”

Plug, with that in mind, works with its partners to improve both the efficiency and sustainability of their operations, helping them meet and exceed regulatory standards and hit climate benchmarks. For more on our leading hydrogen electrolyzer products, please contact us via our website.